Tesla's unique aluminum and steel car body design requires specialized repair techniques to maintain structural integrity and aesthetic appeal. Key steps in Tesla repair procedures include thorough inspection, disassembly, and documentation. Modern advancements like robotic welding, computer-aided paint systems, and frame straightening machines are revolutionizing the industry, ensuring high-quality, safe repairs for Tesla vehicles.

Tesla vehicles, known for their cutting-edge technology, utilize both aluminum and steel in their construction. This article delves into efficient Tesla repair procedures tailored for these materials. We explore the unique challenges and best practices for repairing components, focusing on disassembly, inspection, and advanced restoration techniques. Whether you’re a professional or enthusiast, understanding these Tesla repair procedures ensures optimal results and preserves your vehicle’s structural integrity.

- Understanding Tesla's Material Choice: Aluminum and Steel

- Disassembly and Inspection Procedures for Comprehensive Repair

- Advanced Techniques for Restoring and Strengthening Components

Understanding Tesla's Material Choice: Aluminum and Steel

Tesla, a pioneer in electric vehicle manufacturing, has long been known for its innovative use of materials, particularly aluminum and steel in their car bodies. Understanding the unique characteristics of these materials is crucial when it comes to Tesla repair procedures. Aluminum, renowned for its lightweight properties, offers excellent corrosion resistance and high strength-to-weight ratio, making it ideal for enhancing vehicle efficiency. On the other hand, steel provides exceptional structural integrity and durability, ensuring the safety and reliability of the vehicle.

When repairs are required, especially in cases such as car dent repair or auto glass replacement, understanding these material properties becomes vital. For instance, Tesla’s aluminum panels may require specialized techniques for dent removal to maintain their structural integrity without compromising aesthetics. Similarly, steel components might necessitate specific alignment and replacement methods during vehicle restoration to preserve the original strength and stability of the structure.

Disassembly and Inspection Procedures for Comprehensive Repair

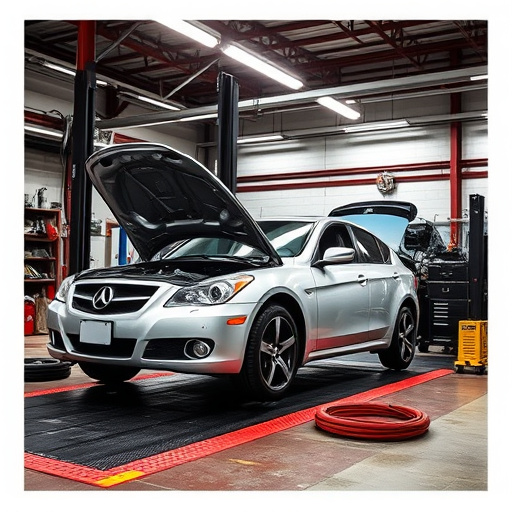

When conducting Tesla repair procedures, especially for aluminum and steel components, disassembly and inspection are paramount. The process begins with a thorough visual assessment to identify any damage or deformity. Using specialized tools, technicians carefully dismantle affected parts, ensuring each component is handled with precision to prevent further harm. This meticulous approach allows for a comprehensive analysis of the extent of the repair needed.

Once disassembled, each piece is inspected individually. This involves checking for cracks, dents, corrosion, or any signs of wear and tear. Advanced diagnostic tools can also be employed to detect underlying issues that might not be immediately visible. Proper documentation of these inspections is crucial for maintaining accurate records and ensuring the effectiveness of subsequent repair procedures, whether it’s car paint repair or more intricate metalwork in a professional car repair shop.

Advanced Techniques for Restoring and Strengthening Components

In the realm of Tesla repair procedures, advanced techniques have emerged to restore and strengthen both aluminum and steel components. These cutting-edge methods go beyond conventional repairs, leveraging specialized tools and materials to ensure structural integrity and aesthetic precision. For instance, in bumper repair, robotic welding technology allows for precise, seamless rejoins, matching the vehicle’s original factory finish. This not only enhances the visual appeal but also reinforces the overall strength of the bumper, crucial for safety and durability.

Similarly, advanced techniques in vehicle paint repair utilize computer-aided systems to match the exact color and texture of Tesla’s sleek aluminum panels. This level of detail ensures that repaired components seamlessly integrate with the rest of the vehicle, maintaining its iconic design and value. Furthermore, Mercedes Benz collision repair experts employ state-of-the-art frame straightening machines to accurately realign distorted steel frames, restoring them to their original specifications. These innovative practices are transforming the Tesla repair landscape, setting new standards for quality, safety, and customer satisfaction.

In conclusion, understanding Tesla’s material choice of aluminum and steel is key to effective repairs. By mastering specialized disassembly, inspection, and advanced restoration techniques, professionals can ensure these vehicles maintain their structural integrity and performance. Adhering to meticulous Tesla repair procedures guarantees the longevity and reliability of both aluminum and steel components, catering to the evolving needs of electric vehicle ownership.